Enclosures protect our electronic devices. This protects our electronics from harsh conditions, corrosion, rust and damage. It is vital that the enclosure protects the device inside, even as its presence may enhance the working quality of the device. It puts the entire electronics, switches, knobs, and wires together. To ensure the durability of electronic equipment’s durability, customize the most suitable aluminum electronic enclosure.

Analysis of the three main functions of the aluminum electrical enclosure below

Protect against water ingress:

Did you know that in Shenghai Aluminum, we have IP68 waterproof aluminum enclosures? IP68 is the highest waterproof level, and electronic products in some fields will be used in outdoor areas. Due to exposure to harsh weather conditions, they are often exposed to wind, rain or even submerged in water, but with an IP68 aluminum extrusion case, the electronics can be submerged in a certain level of water.

Blocks hazards, scratches and damaged electronic components:

Using aluminum alloy shells for electronic instruments can directly prevent the human body from contacting electronic components, reduce wear and damage to the instrument, and even because the extruded aluminum enclosure box protects the circuit system, there is no leakage. Although aluminum alloy itself is a conductive material, it can be treated with anodic oxidation. It directly makes the extruded aluminum enclosures electronics produce insulating properties, which is very safe.

Now that we have mentioned the different uses of enclosures let us discuss the different electronic enclosures types. The components of the project box must be chosen carefully to ensure that it is suitable for its function. We have two main types of electronic enclosures, plastic and metal.

Plastic cases are less expensive and lighter than metal cases. Because of its non-conductivity, it ensures that the electronic equipment inside will not hurt people when touched. An example of a plastic housing is an ABS plastic housing or acrylonitrile butadiene styrene, a tougher thermoplastic.

Metal enclosures or boxes are usually made of stainless steel or aluminum. It’s more expensive than a plastic case, but don’t worry; it’s worth the price. Since the metal case is more durable, it can withstand the device’s weight and RF shielding. In general, aluminum housings are highly conductive, which means better electronic performance.

Excellent thermal management means your electronics don’t overheat, affecting the device’s functionality. The anodized aluminum case provides better protection for the case itself, making it last longer through oxidation. Additionally, the anodized aluminum enclosure is available in custom colors.

Why choose aluminum profiles as electronic enclosures

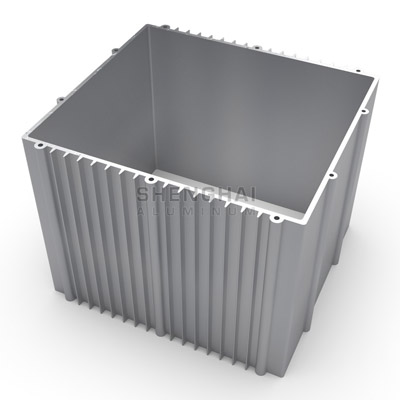

Aluminum profiles have several advantages as electronic enclosures, including lightweight, easy processing, good thermal conductivity, strong corrosion resistance, good aesthetics and moderate cost. The lightweight characteristics of aluminum sections help reduce the weight of the entire electronic product, making it easy to carry and move; aluminum profiles are easy to process and form, and can produce electronic housings of various shapes and sizes; aluminum is an excellent thermal conductivity material, It can quickly conduct the heat generated inside the electronic product to the outside, which is conducive to maintaining the stable operation of the electronic product; the aluminum material has good corrosion resistance, and can keep the appearance and performance unaffected in various environments; the appearance of the aluminum extrusion profile is smooth and smooth , Various colors and textures can be produced through surface treatment and painting, making the appearance of electronic products more beautiful and generous; the cost of aluminum materials is relatively low, suitable for making large quantities of electronic product casings, which is conducive to reducing production costs.

Manufacturers needing aluminum profiles for electronic enclosures can contact us anytime.