The first part of LED lamps is LED light emitting diode, lamp shell, PCB circuit board and lamps which are for LED products cooling progress, the choice of aluminum substrate is also very important.

LED light-emitting diode as the theme of lamps and lanterns, also of the main components affecting the service life of lamps and lanterns, is also a primary color saturation, choosing the appropriate, different scales, different luminous intensity is different also, do not covet is cheap, use small chips, due to the formation of the serious influence life, this is a major cause of chip price difference, if attaches great importance to quality, attaches importance to continue,Then please choose the right chip.

Cooling the main reason for the selection of materials, is also the main factors influencing the led lamps, led rate of progress, if the corresponding heat quality can not progress, is used in small range of high brightness chip, according to the development trend of lamps and lanterns, the demand for heat dissipation is very outstanding, high temperature resistant, using high-tech, such as using yellow light shadow heat dissipation base board, LED power can progress together,It is also an important catalyst for LED progress in quality.

Prophase choose pure aluminium radiator, short production skills, capital is low, the progress of skills, seeking high thermal conductivity, pure copper radiator into everyone’s vision, although progress relative to the aluminum alloy heat dissipation coefficient, but capital is difficult to control, and the market of pure copper radiator and evil people mixed up of data, a lot of people don’t choose the real pure copper, copper and aluminium under contact, connection capital to break through the bottleneck, the currentIn terms of finding a good balance.

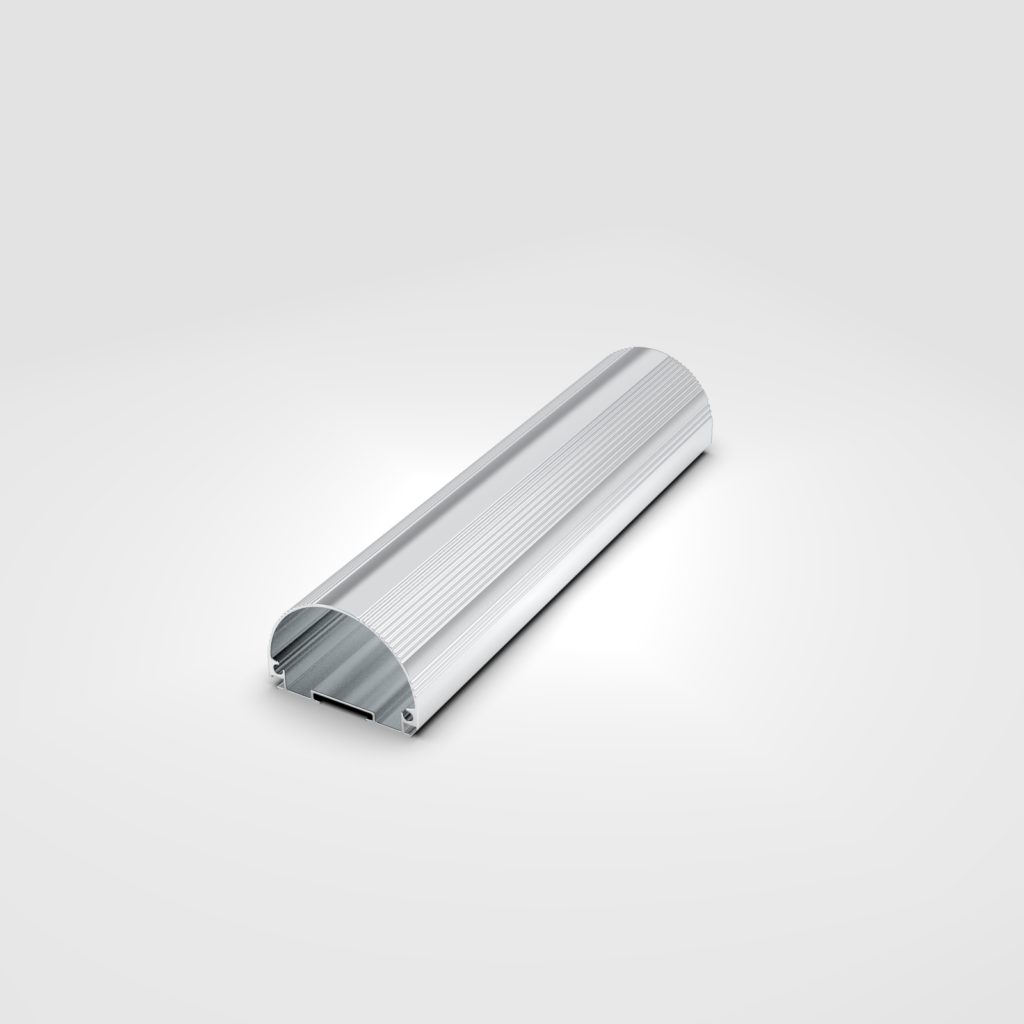

The shell of LED lamps is made of engineering plastic die-casting, and there is still a large amount of aluminum alloy shell. For the transmission power of lamps,, choose casting zinc alloy shell, the effect is better than other materials, such as 6063-T5 aluminum alloy, aluminum has a good thermal conductivity effect, and can be done very thin, the maximum heat dissipation area of progress, in addition to the generation of engineering plastic die-casting speed is better than aluminum, low cost, another is the future trend tends to aluminum.

LED lamps and lanterns generation threshold is very low, compared with some low skill level,LED lamps and lanterns make data selection compared with the impact of the market, product quality is good and bad at the same time, this is one of the reasons the formation of LED lighting lamps and lanterns can not be promoted, as the price of consumers is not selected, the quality of defects is not good enough.