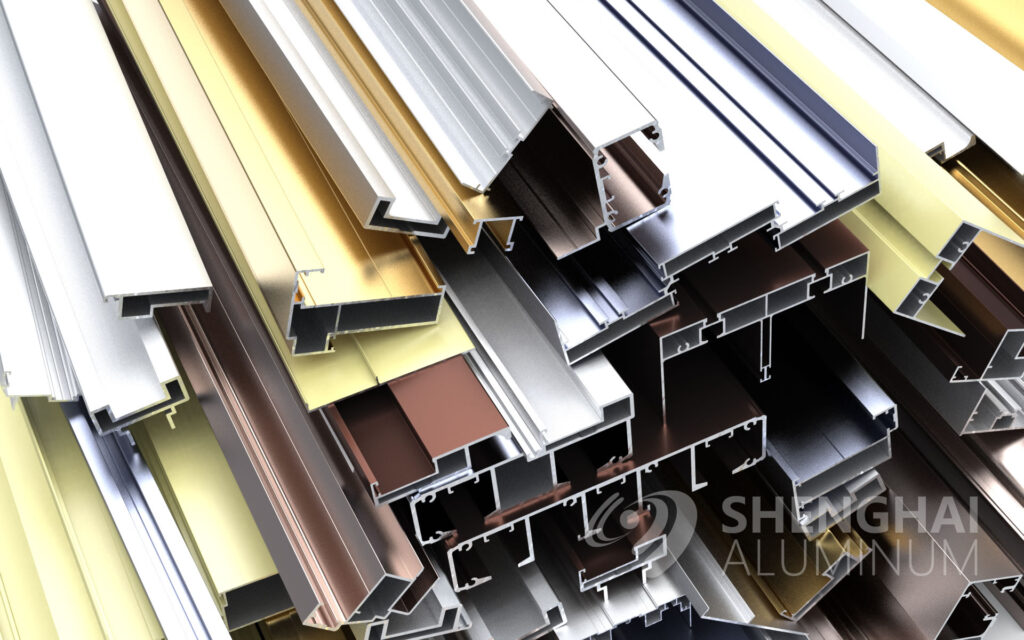

As an important downstream processing product of the aluminum industry chain, aluminum profiles have shown broad application prospects in daily life due to continuous improvement of technology, fine control of costs and enhanced awareness of resource recycling. Now, look deeper at the cost per ton of aluminum alloy profiles and their pros and cons.

How to calculate the price of aluminum alloy profiles

The price calculation of aluminum alloy profiles usually involves multiple factors, including material costs, processing costs, market demand, model specifications, surface treatment, etc. The following are some of the main factors that affect the price of aluminum alloy profiles:

Material cost: The price of aluminum alloy profiles is firstly affected by the cost of raw materials. Different types of aluminum alloys have different costs, and alloys with higher strength and better corrosion resistance are usually more expensive. Aluminum alloy prices will also be affected by supply and demand in the aluminum market and fluctuations in the international market.

Model Specifications: The size, shape and specific specifications of the profile affect the price. Larger sizes and more complex geometries tend to require more material and tooling costs and therefore be more expensive.

Surface treatment: If the aluminum alloy profile needs surface treatment, such as anodizing, spraying, electrophoretic coating, etc., these treatments will also increase the cost because they involve additional processes and materials.

Processing technology: If the profile needs further processing, cutting, punching, welding, etc., these processing processes will also affect the price. Complicated processing requires more manpower and equipment input, thereby increasing costs.

Market demand: Market demand has a direct impact on the price of aluminum alloy profiles. When supply and demand are tight, prices can rise, and vice versa.

Production batches: High-volume production often results in lower unit costs because the costs can be spread over more products. Therefore, the quantity purchased may affect the price.

Brands and Suppliers: Aluminum alloy extrusion prices may vary between brands and suppliers. Well-known brands usually have higher credibility and quality assurance, but they may also be more expensive.

Why choose an aluminum profile manufacturer

Shenghai Aluminum is a professional aluminum extrusion factory with a professional technical team and advanced machine equipment. If you are looking for aluminum profile project, choosing aluminum profile manufacturer is the best.

Quality Assurance: Excellent aluminum profile manufacturers usually follow strict quality control standards to ensure their products’ stable and consistent quality. This helps you obtain high-quality aluminum profiles as expected, reducing the risk of production delays or equipment damage caused by quality issues.

Technical Support: Experienced manufacturers usually have a team of experts who can advise you on design, engineering and applications. They can help you choose the aluminum profile type, size and shape that best suits your needs and provide advice on usage.

Customization Capabilities: Some aluminum extrusion producers can produce aluminum extrusions of specific sizes, shapes and characteristics according to your requirements. This helps to meet the needs of special projects, and improve production efficiency and product performance.

Cost-effectiveness: Choosing the right producer can help you balance quality and cost. High-quality aluminum profiles may have a longer service life, reducing maintenance and replacement costs.

When purchasing aluminum profiles, it is very important to choose the right aluminum profile manufacturer. Not only can you get technical support, but you can also save costs.