Choosing the right aluminum profile supplier is important, especially if you are looking for a reliable source for your specific project or business needs. Here are some steps to help you choose an aluminum profile supplier:

Determine Your Requirements:

Define your project’s requirements and specifications, including the type, size, and quantity of aluminum profiles you need. Be clear about the alloys, finishes, and tolerances required.

Quality Standards and Certifications:

Ensure that the supplier adheres to relevant quality standards and certifications. For aluminum profiles, these include ISO 9001 or other industry-specific certifications. Ask for proof of compliance.

Product Range:

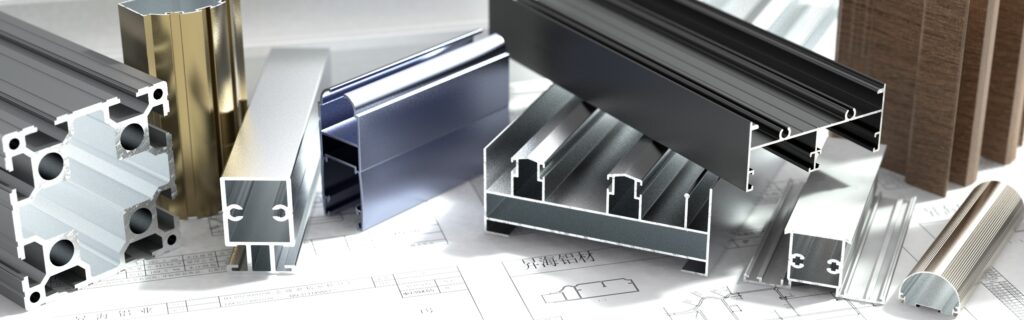

Consider the variety of aluminum profiles the supplier offers. Make sure they have the specific profiles you need. A supplier with a diverse product range may be more versatile and accommodating.

Manufacturing Capabilities:

Evaluate the supplier’s manufacturing capabilities, including their equipment, production capacity, and lead times. This is crucial to meet your project timelines.

Customization Options:

Check if the supplier offers customization services. Some projects may require unique profiles or specific finishes. Ensure they can meet your customization needs.

Communication and Support:

Assess the supplier’s communication and customer support. Responsive and helpful customer service can make your procurement process smoother.

Sample Request:

Before making a large order, request samples of the aluminum profiles you plan to use. This allows you to evaluate the quality and suitability for your project.

Shenghai Aluminum Will Be Your Best Aluminum Profile Supplier In China

We have expanded into markets in many countries, including Kuwait, Mexico, Mauritius, the United States, and Saudi Arabia. Our aluminum profile offerings encompass a wide range of products, including doors, windows, cabinets, T-slot profiles, ceilings, curtain tracks, and decorative materials such as tile trim. Shenghai Aluminum handles everything from profile extrusion to surface treatments (anodizing, powder coating, CNC machining, etc.), ensuring a one-stop production process. This not only reduces costs for our customers but also shortens delivery times. If you want your products to gain a competitive edge in the market, please contact us immediately to receive a quotation.