Most of the aluminum tubes on the market are produced by the conventional combined die welding and extrusion process, and the welding line cannot be completely avoided, especially when there is a dark line after oxidation. Extrusion production adopts a short round bar, high temperature and slow extrusion process, especially the “three temperatures” should be controlled. The aluminum bar, extrusion cylinder, and die should be kept clean. The aging time and temperature are based on the thickness of the pipe wall. The size of the pipe diameter can be adjusted appropriately.

The currently used aluminum tube extruder includes an extrusion box and a cylinder. The heated aluminum block is put into the extrusion box from the feed port. The cylinder starts to work so that the extrusion beam pushes the aluminum block toward the extrusion die. The aluminum block in the state has good plasticity. When the temperature of the aluminum block decreases, the plasticity will also decrease. Under the action of certain pressure and speed of the extrusion beam, the extrusion pad pushes the aluminum block to produce plastic flow and extrude from the extrusion die. , To obtain the aluminum tube with the required cross-sectional shape and size;

During the extrusion process, the aluminum block is in a strong pressure state in the extrusion deformation zone, which can give full play to its plasticity and obtain a large amount of deformation. At the same time, the extrusion deformation can be improved The structure of metal materials improves its mechanical properties, especially for aluminum blocks with extrusion effects. After quenching and aging, the longitudinal (extrusion direction) mechanical properties of the extruded products are much higher than similar products produced by other processing methods. Press processing also has great flexibility. You can produce products with different shapes, sizes, specifications and varieties on the same equipment only by replacing the extrusion die, and the operation of replacing the extrusion die is simple, convenient, time-consuming, and efficient. However, there are still big problems in the forming of some double-layer seamless aluminum tubes. Therefore, it is necessary to improve this situation.

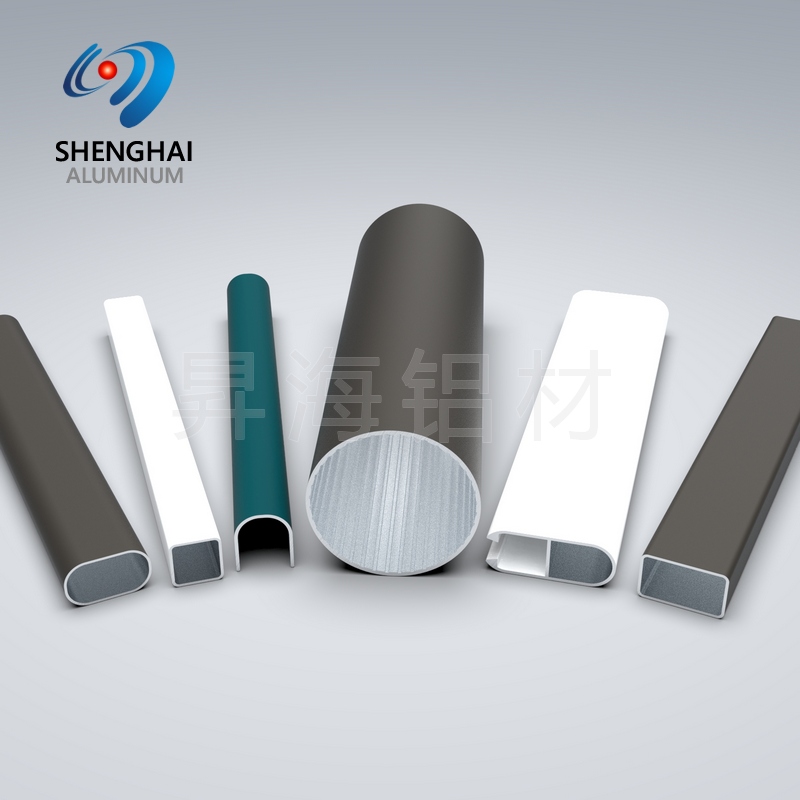

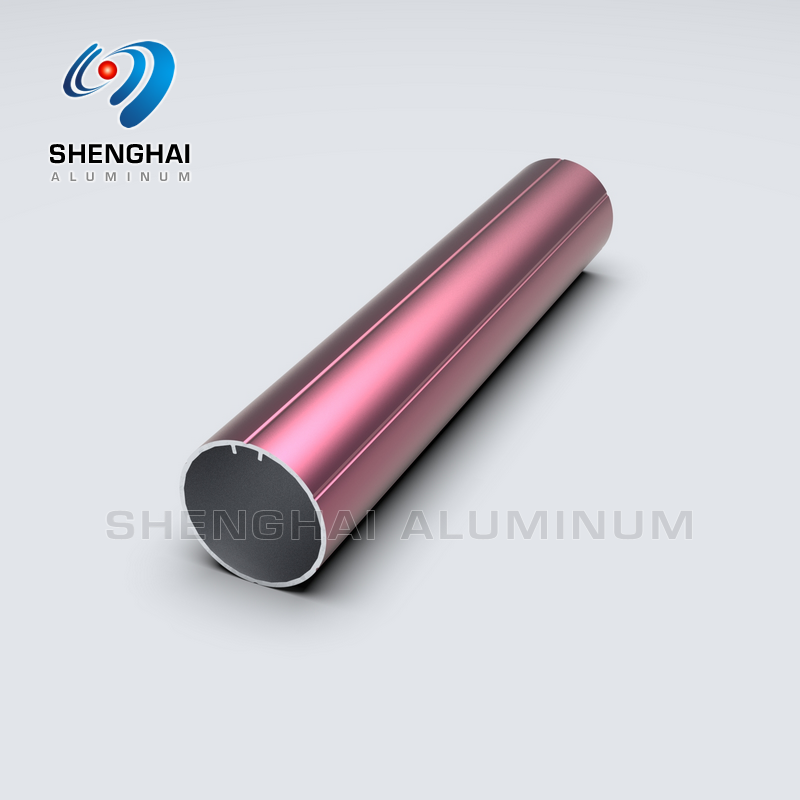

Seamless aluminum tubes are generally perforated and extruded. Because seamless aluminum tubes have the characteristics of small specific gravity, easy processing, and high mechanical strength, in fact, the requirements for the production process of seamless aluminum tubes are relatively strict and delicate.

However, some problems should be paid attention to when making, in order to produce seamless aluminum tubes of satisfactory quality. Let me share with you the problems that need attention in the production of seamless aluminum tubes and some successful practical experiences.

Large seamless aluminum tubes are generally formed by hot extrusion and then undergo subsequent effective treatment. The small seamless aluminum tube can be hot extruded or cold stretched, and then undergoes subsequent effective treatment.

The aluminum oxide hydrate produced during the production of seamless aluminum pipes needs to be continuously extruded, and violently dehydrated during the extrusion process to form blisters. In order to prevent blisters on the seamless aluminum pipe, the round aluminum rod for extrusion must not have rolling cracks; it must not be stored in a humid environment. The content of sodium hydroxide in the cleaning solution should be about 30%. Control the aluminum ion content in the cleaning solution.

Consultation Tel:+8613172378271/Email:truda@shenghai-alu.com