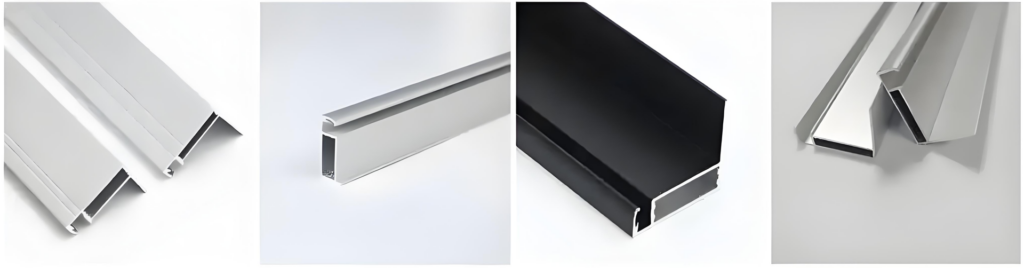

Aluminum Solar Profiles

- Hundreds of Molds Available for Solar Frames

- 100% Quality Inspection at Every Production Stage

- Seamless Connection Without the Need for Screws

- Enhanced Protection Compared to Frameless Solar Panels

Aluminum Solar Profiles Application

Ground Photovoltaic Brackets

Suitable for large-scale photovoltaic power stations, typically utilizing H-type, C-type, or T-type aluminum profiles to ensure high load-bearing capacity.

Roof Photovoltaic Brackets

Designed to be lightweight, making them ideal for residential and commercial building rooftops. Common types include pitched roof and flat roof brackets.

Carport Photovoltaic Brackets

Combining shading and power generation functions, these brackets are widely used in residential areas, shopping malls, and industrial parks, optimizing land utilization.

Agricultural Photovoltaic Brackets

Used in agrivoltaic projects, these brackets provide stable support for photovoltaic systems in farmland, greenhouses, and similar environments.

Characteristics of Aluminum Solar Profiles

High Strength and Lightweight

Aluminum alloys (such as 6061 and 6063) offer an excellent strength-to-weight ratio, significantly reducing overall weight while ensuring bracket stability, making transportation and installation easier.

Strong Corrosion Resistance

Solar brackets are exposed to outdoor conditions for extended periods, facing wind and rain erosion. Aluminum profiles are typically treated with anodizing, powder coating, or electrophoretic coating, effectively resisting oxidation and corrosion. This makes them particularly suitable for harsh environments such as coastal areas and high-humidity regions.

Stable Structure and Easy Installation

Manufactured using precision extrusion technology, aluminum solar profiles feature a well-designed cross-sectional structure that can withstand strong winds, heavy rain, and snow loads. Additionally, their modular design simplifies the installation process, improving construction efficiency.

Environmentally Friendly and Recyclable

Aluminum is a 100% recyclable material, aligning with sustainable development goals while also reducing long-term maintenance costs.

How to Choose the Right Aluminum Solar Profile

Select the Appropriate Surface Treatment Based on the Environment

Anodizing: Offers strong corrosion resistance, ideal for humid environments.

Powder Coating: Enhances salt spray resistance, making it suitable for coastal or highly polluted areas.

Electrophoretic Coating: Improves wear resistance and extends service life.

Choose the Right Profile Cross-Section Design

C-type, U-type, and H-type structures: Provide higher load-bearing capacity and wind resistance.

Trough profile: Suitable for modular assembly, enhancing installation flexibility.

Consider Customized Processing Requirements

Some suppliers offer customized services such as cutting, drilling, and splicing, allowing for optimized design based on project requirements and improving installation efficiency.

Market Prospects of Aluminum Solar Profiles

With the rapid growth of the global photovoltaic market, the demand for solar brackets continues to rise. Due to their superior performance, aluminum alloys are increasingly used in photovoltaic bracket systems. Additionally, the rise of smart photovoltaic systems has set higher standards for the structural design and processing precision of aluminum profiles. In the future, lightweight, high-strength, and intelligent aluminum solar profiles will become the industry’s key development trend.

To Get A Quote