Extruded Aluminium Sections

Extruded Aluminium Sections

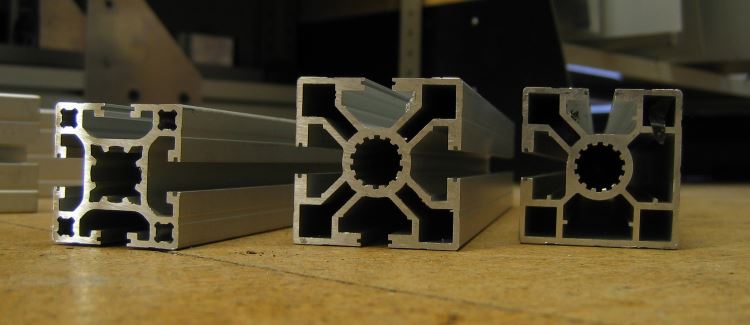

Aluminum extrusions are linear aluminum products highly valued in a wide spectrum of structural applications due to aluminum’s high strength-to-weight ratio and the cost effectiveness of the metal extrusion process. Like other types of metal extrusions, extruded aluminum is either hot extruded or cold extruded through a die, shaping aluminum stock into various types of extruded aluminum shapes, such as angles and beams, aluminum channels, aluminum profiles or aluminum extruded tubing.

Extruded aluminum products like aluminum channels, shapes and profiles are both strong and lightweight, making them perfect for structural applications such as light poles, building and window frames, lighting fixtures, car bumpers, hardware joints, trim, and many other uses in construction, industrial and automotive industries. Shapes and channels can be extruded into complex, precision tolerance shapes to interlock with other aluminum channels or structures, or they may be extruded into heat sinks for cooling electronics, refrigerators and heat engines. Because aluminum is strong, rust and temperature resistant, easily fabricated and 100% recyclable, aluminum and aluminum alloy extrusions are often the first choice in building or structural materials.

The number of industries which use aluminum extrusions is both extensive and diverse since a wide number of shapes are achievable through the extrusion process. For example, extruded aluminum channels make great components for automotive and transportation construction, as it is light and corrosion resistant; aluminum channels and profiles are used in vehicles such as trains, SUVs, semi trucks and cars for parts and components including panels, window panes, runners and bumpers. In addition, machinery and industrial equipment such as scaffolding, process and mining equipment use extruded aluminum tubing, shapes and profiles as lightweight, durable equipment components, while many types of office and hospital furniture use aluminum tubing and channels in their construction. The building, architectural and construction industries use aluminum profiles extensively, whether it be practical application such as for structural and ceiling beams or for aesthetic applications such as decorative trim and window paneling. Capable of being extruded through complex dies into close-tolerance shapes, small extruded aluminum shapes are frequently fabricated into medical and electronics components such as heat-absorbing and dissipating heat sinks.