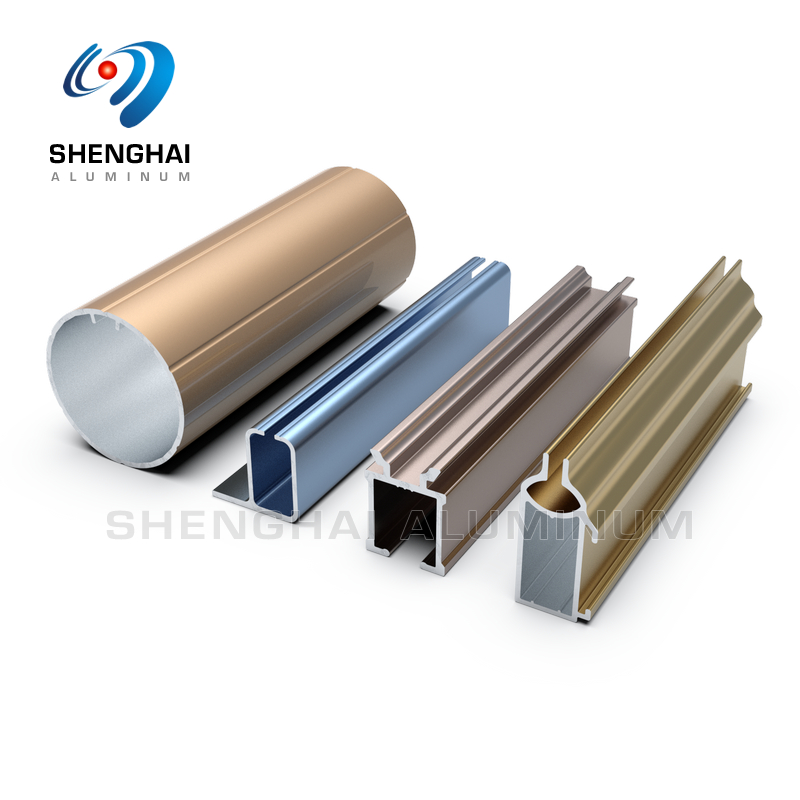

Aluminum has a wide range of uses and relatively low cost. It has a very high strength to weight ratio and corrosion resistance. It is environmentally friendly and can accept high performance coatings.

After deciding to design a custom aluminum profile, you need to make some important choices. One such choice is which surface treatment option to choose.

The choice of surface treatment is important for two main reasons:

Reason one, surface treatment can improve corrosion resistance.

Aluminum has a natural oxide film that protects it from corrosion. This oxide film is sufficient for many applications. But in some circumstances, additional protection may be needed.

Reason two, surface treatment can enhance the appearance of aluminum.

Depending on what you want to achieve, you need to choose the right finish. Maybe you want something bright in color. Maybe you want to achieve the “mirror” effect. You need to choose a finish that will give you the look you want.

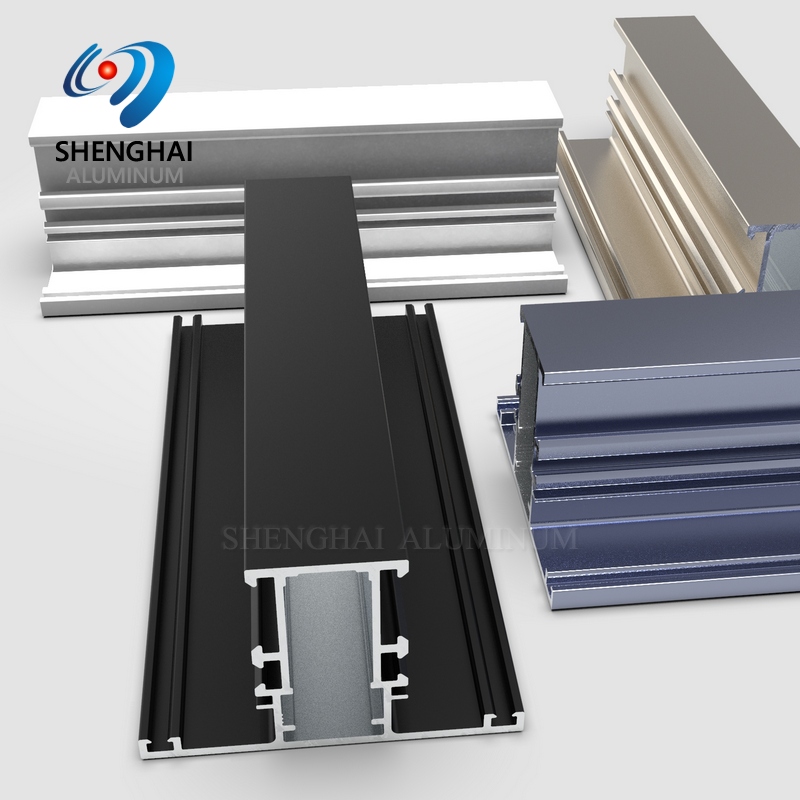

The following are six different types of aluminum profile surface treatment:

Mechanical finishing

Aluminum can be polished, sandblasted, brushed, ground or sanded. These surface treatments can improve the quality of the surface or prepare for other surface treatments.

Pretreatment

Aluminum can be etched or cleaned with alkaline or acidic materials. A pretreatment coating is then applied. The coating enhances the adhesion of the powder or paint and provides corrosion resistance.

Chemical finishing

The extruded parts can be polished and impregnated to give the aluminum a mirror-like effect. To do this, a technician places the profile in a special dip (a mixture of hot phosphoric acid and nitric acid). After bright impregnation, profiles can also be anodized, thickening the corrosion resistant oxide layer of the metal.

Anodized

This electrochemical process provides additional protection in addition to the natural oxide film. A durable porous anodized layer is formed on the aluminum surface. Anodized alumina can also accept bright colors. Anodized aluminum or its alloys improve its surface hardness and wear resistance.

Paint spraying

Spray paint is the use of compressed air to disperse liquid paint (commonly known as paint) into paint mist particles adhere to the profile surface, these coatings have a variety of colors, liquid paint usually contains volatile organic compounds (VOCs). They are removed during curing or baking. As the VOCs disappear, a large number of solids form thin films on the profiles.

Powder coating

Powder spraying is the use of powder spraying equipment (electrostatic spray molding machine) to spray powder coating to the surface of the workpiece, under the action of static electricity, powder will be uniformly adsorbed on the surface of the workpiece, the formation of powder coating; Powder coating after high temperature baking leveling curing, into a different effect (different kinds of powder coating effect) coating. At the same time, powder spraying does not contain volatile organic compounds.

Heat tranfer printing

Have you ever seen an aluminum extruded product that looks like wood? After coating with powder base, the profile can be heat transfer. The technician wraps the profile in a film with a pattern. The thermal transfer process transfers the pattern directly to the extruded profile.

Brief summary

Whether you’re designing a new building or the interior of a car, aluminum extrusions are an important part of your project. Choosing the right finish will ensure that your extruded profiles have the right appearance and appropriate corrosion resistance.